Brake squeal is a common problem often because of worn brake hardware, pads, or rotor finish. But are squeaky brakes risky or just traumatic?

The brakes are your automobile’s most critical protection function. Made up of several distinctive elements and additives, they may be designed to be noisy once they’re going bad, which is a good thing. It’s virtually higher to discover your brakes are going awful from hearing a squeak than by using no longer being capable of stopping! Fortunately, maximum brake noises are taken into consideration every day and do now not suggest a hassle.

Constant or unusual brake noise may be a sign that your brake hardware truly desires to be lubricated. Or it may be a caution that components in the brake machine are wearing out or want to be serviced. So take the commonplace experience method. Check your brakes in the event that they’re always noisy or the noise appears to be increasing. With brakes, it’s usually better to be safe than sorry.

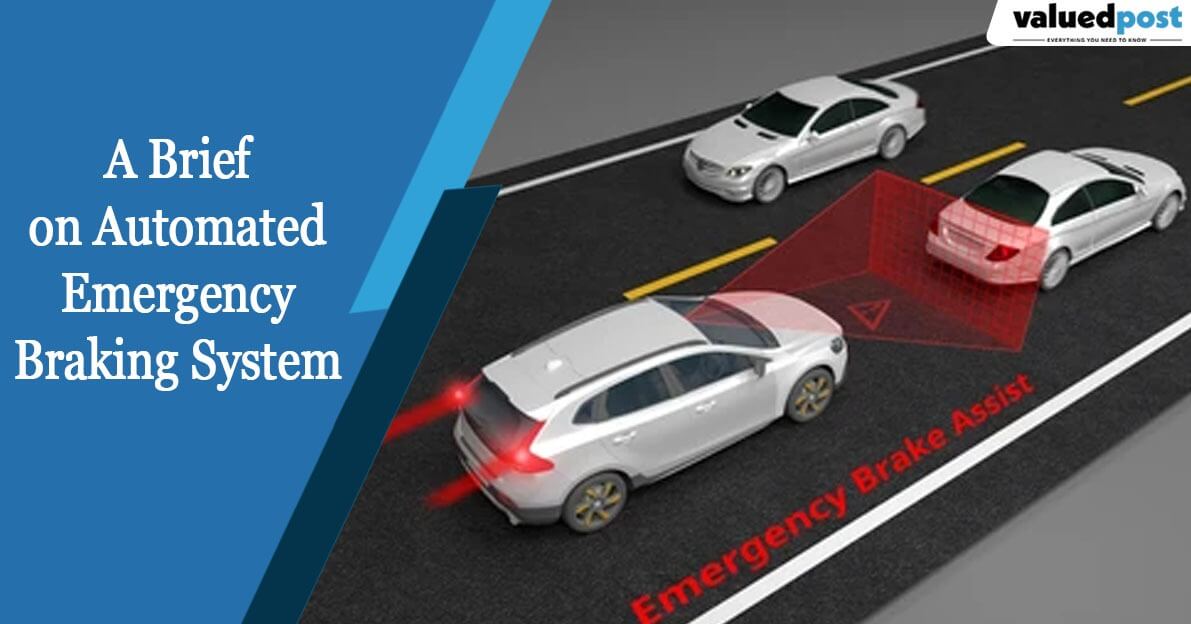

How Brakes Work

Brake pads are fabricated from friction cloth attached to a metallic backing plate. When you practice the brakes, fluid stress forces the brake calipers to clamp the pads down on the disc rotors, developing heat. It is this warmth (friction) created by means of the pads urgent in opposition to the rotors that slows and then subsequently absolutely stops your vehicle.

Why Are My Brakes Squeaking?

Brakes squeak, squeal, or screech whilst vibrating brake pads produce a sound in a selected frequency. That sound, however, doesn’t suggest your brakes are failing. If your brakes grind or snatch, or your automobile pulls to one facet when braking, that’s a one-of-a-kind tale. In the ones, instances ask a mechanic to test your brakes straight away.

Specific Causes of Brake Noise

Temperature Change

That, or in a single day a mild layer of rust can form on a rotor, making brakes squeal. Once brake pads and rotors warm-up, the noise stops. Nothing to worry about.

Wear Indication

Some pads include a put-on indicator that produces a noisy squeal when the friction fabric is worn down, indicating the pads want changing.

Brake pad friction material can be made from composite substances together with semi-metallic, non-asbestos natural [NAO], low-steel NAO, and ceramic.

Semi-steel pads have wonderful stopping electricity, but are noisy and cause untimely rotor wear.

NAOs lessen vibration, however, wear speedy.

Low-steel NAO additionally has exquisite preventing strength, but is noisy and dusty.

Ceramic pads, the most expensive, provide suitable preventing power, plus are quieter and produce little rust or dust.

Worn, Broken, or Missing Brake Hardware

Worn or lacking shims, clips, springs or unfastened fasteners are the primary causes of brake noise. Any of these will purpose pads to pull at the rotors, overheat, vibrate, and wear erratically and more speedy.

How to Fix Squeaking Brakes

Replacing brake pads and the hardware causing the squeak may be a DIY job. Many automotive supply stores will lend you specialty equipment to replace brake pads. Rotors that can be glazed (smooth and shiny) or scored from immoderate pad wear and tear, or a brake pedal that pulsates up and down when stopping, all indicate the rotors need to be refinished or replaced.

Do a little research to decide if you can replace the rotors yourself. And recollect protection first. Always wear masks, protection glasses, and gloves when changing brakes.

Pro Tips for Fixing Squeaking Brakes:

Always replace all brake hardware (anti-rattle and spring clips) while installing new pads. Many packages call for masking the backing plates with anti-squeal lubricant, excessive-temperature silicone insulation gel, or Teflon shims that absorb braking vibration.

Clean all hardened steel components (inclusive of caliper slide pins) by soaking them in a non-chlorinated brake cleanser (not degreaser) and using a plastic brush. Do not “break” the hardened end with the aid of cleaning with a report or twine brush.

Be positive to ease all contact factors of rust and corrosion and lube all mating elements and slide pins with special brake grease or anti-capture compound.

Avoid getting lubricants or greases at the pad friction surface.

When completed, region a pan beneath the rotors and give them (now not the pads) an intensive cleansing with brake cleaner to do away with any grease or fingerprints before installing the wheel.